Improvements are an inevitable gateway to success.

If your business is stagnant or if you want more profits or if your business is slowing down or you want to simply have your business perform better…its time to conduct GAP Analysis. Performing a GAP ANALYSIS is much more than a simple diagnosis. It is one of the most efficient ways to detect gaps in processes, helping companies to review applied concepts. Through GAP Analysis, it is possible to obtain indicators, planning improvements and consequently provide growth in the business with cost reduction, waste, rework, in addition to effective quality on products or services.

As time passes by, every company is subject to external influences or new market demands, which makes us reflect on what changes must be made to achieve real results… that’s where the business sense to remake plans must be initiated.

Moments like we have been nowadays, on a global scale, are opportunities to reinvent ourselves.

Where to start? A very first step would be questioning the business model, then identify what is working well and finally, what needs improvement.

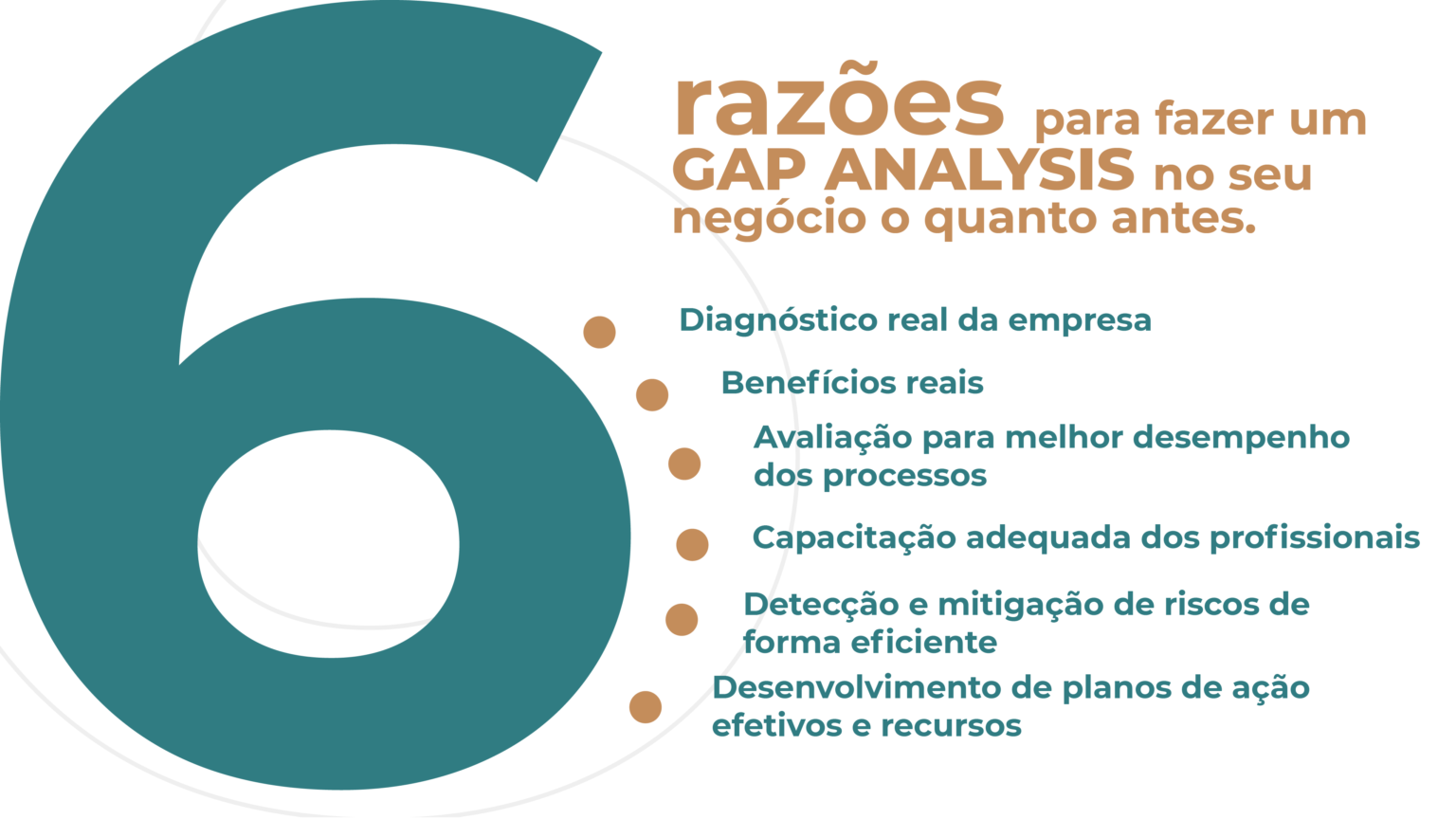

Therefore, we give you 6 reasons to apply a GAP Analysis in your business right now!

- DELIVERS A REAL COMPANY DIAGNOSIS:

#GAPANALYSIS is an effective method for this assessment, identifying how your business is and how you would like or should be working.

As it is a method that uses quality tools, GAPs are identified and their criticality evaluated, taking into account what could be improved, results expectations, which ones can be optimized or automated, both in production and for quality, besides considering national or international legislation or regulations for their evaluation.

This diagnosis can have either a wider or narrower focus such as the evaluation of processes through the implemented quality system, equipment qualifications, validations performed (processes, cleaning, systems and methodology), in addition to business outcome expectations.

- REAL BENEFITS FOR YOUR BUSINESS

- Review of the current approach of its management and the planning for implementing improvements necessary to achieve the objective the company aims;

- How to engage the team with focused efforts in targeted actions;

- Allows a current management system overview;

- Better distribution of resources and maximizing the ROI (Return on Investment);

- Evidence of Risks (Threats and Opportunities) in internal processes and in the market;

- Development of indicators, Whether there is waste, loss, rework or reprocess;

- Survey of what trainings are necessary to the employees involved for optimization and real development of the process;

- Detection of new projects and their steps to ensure continuous improvement;

- EVALUATION FOR BETTER PROCESS PERFORMANCE

With GAP ANALYSIS it is possible to identify, during process, what can be improved in relation to the indicators of effectiveness and efficiency.

It makes it possible to verify whether all indicators produce the results you want to and whether they are the correct evaluation for a given process.

Indicators are tools which generate data that help in decision making and guide organizations, managers, process owners.

Because of this, it is necessary that while creating the indicators to ask the question: “What to measure?”.

Generating data that does not bring objective meaning may cause risk to managing process performance and its desired effectiveness. This leaves managers blind to assertive decision making. Therefore, a performance management can be used as a basis of a good old known tool, The PDCA cycle (Plan, Do, Check, Act).

- ADEQUATE TRAINING OF PROFESSIONALS

Some of the most recurring questions for many organizations are:

- How can I develop my team’s results?

- How to determine operating result goals?

- How to engage team for the purpose of the process or business?

- Are we being clear in internal communication?

A company seeking answers to any of these questions, it is through a GAP ANALYSIS in which it is possible to evaluate all of this, focusing on a training the team really needs, not the “same old, same old”.

Adequately empowering the employees involved in the process is a real gain for the company. The higher the qualification, the greater the understanding of people in relation to what is right and wrong and what was established by the organization of what should be accomplished to achieve operational excellence. Detecting these gaps in training is fundamental to the good performance of the processes beyond the actual planned result.

- EFFICIENT RISK DETECTION AND MITIGATION

With thorough assessment of an organization’s processes it is possible to identify the risks (threats and opportunities) and verify the degree of priority regarding severity, probability of occurrence and detection of these risks.

With this, you can establish criteria to plan improvements in the company. Such GAPs are treated according to their criticality, in the short, medium and long term.

- DEVELOPMENT OF EFFECTIVE ACTION PLANS AND RESOURCES

Have you had the experience of performing various actions and not having an effective result? This is where GAP Analysis acts, developing projects or planning according to the criticality of each GAP found.

When verifying each process and what caused the existing gaps, it is necessary to start the stage of planning and tracing the most appropriate actions so that they are effective. To achieve concrete solutions, it is necessary to consider not only success cases and validated actions, but also the cost of implementing each solution and evaluating the resources already available. It is essential that planning deadlines are established for actions, costs, resources and milestones to verify their development and progress. Through a GAP Analysis, it is possible to plan this and how best to perform the actions.

Finally, it is essential to say that only a survey of all GAPs on the processes is not the final solution. You need to make sure that the solutions designed for each GAP are effective and that they are actually put into practice. Another challenge is to monitor actions and maintain such results and planning.

The important thing is not to “skip steps” in order to solve GAPs more quickly. If this is the case, there is a risk of extra costs or even non-effective solutions, leading to the recurrence of GAP or the emergence of new GAPs..

Know more about our gap analysis service on https://www.kivalitaconsulting.com/en/gap-analysis-2/

Contact Kivalita Consulting and request a gap analysis quote!