Barbara Guelfi

In this article it will be possible to know what HACCP (or APPCC in Portuguese), its application and benefits vis-a-vis food companies, and how to develop it in 12 steps.

What is HACCP or APPCC?

The acronym HACCP is of English origin, the abbreviation of which is Hazard Analysis & Critical Control Point, or in Portuguese commonly called APPCC (Hazard Analysis and Critical Control Points). It is a methodology to ensure, analyze, identify and control the critical points of a process from the sanitary point of view, considering from production, distribution to food consumption.

What is the Origin of HACCP?

In the 1960s, the U.S. military and pillsbury developed a thorough study of food management in the space environment. That’s because NASA (National Aeronautics and Space Administration) requested such a study so that the crew could avoid the occurrence of incidents of indisposition or food poisoning on missions as much as possible. This technique aimed to evaluate the food production processes in detail. Thus, after numerous tests, this system has expanded to the HACCP/APPCC that we know today.

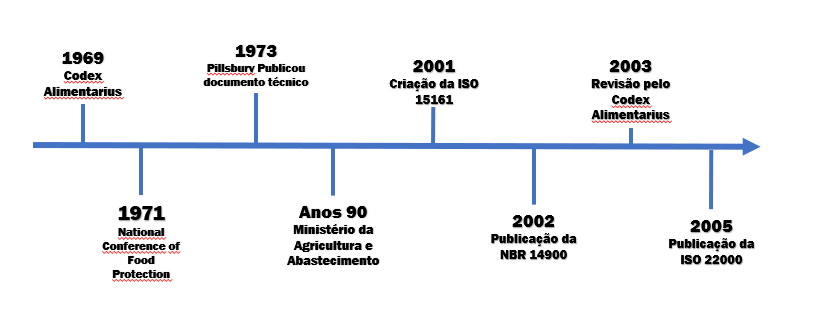

Starting in 1969, the Codex Alimentarius committee added in its Codes of Food Hygiene Practices the guidelines of the HACCP/HACCCC system program. However, it was not only in 1971 that it was presented to the public for the first time during the national conference for food protection held in the United States.

With the search increasing on the procedures and how to apply the necessary requirements of this system, pillsbury company published a technical document elucidating how to develop this analysis in detail. In Brazil, these rules only came to be implemented in the 1990s, through ordinance 1428 of the Ministry of Health for industries in general and the Ministry of Agriculture and Supply of Brazil applying in companies in the field of fish and derivatives.

In 2001, ISO(International Standardization Organization) established guidelines for the application of ISO 9001 but specifying for the beverage and food industry area through ISO 15161:2001. Among the recommendations of this regulation, the HACCP rules were being fully considered.

In 2002, NBR 14900 was published in Brazil by the Brazilian Association of Technical Standards (ABNT), which was based on the principles of the Codex Alimentarius, in addition to considering some points of ISO 9001 and ISO 15161:2001.

When it was 2003, Codex Alimentarius reviewed the Codes of Practices of Food Hygiene. This has contributed to the provisions of some HACCP requirements in the Code, further increasing the scope for inspection and application. With this, it facilitated the understanding of some processes in the document.

And finally in our history, in 2005 ISO published the ISO 22000 standard, recommending the Requirements of The Food Safety Management System, and can be applied to any company that operates in the food production chain.

In this, elements of a Quality Management System, prerequisites of Good Manufacturing Practices (GMP) and principles of the HACCP system were considered.

How to apply HACCP to your processes?

Standards recognized today as ISO 22000, SQF 2000, BRC, among others for referencing the HACCP methodology by the Codex Alimentarius Code, this will also be our reference for explanation.

Therefore, the HACCP development procedure in your processes should follow these steps:

- Team Building

- Product Description

- Identification of Intent to Use

- Construction of the process flowchart

- On-the-spot confirmation of the Flowchart

- Listing of all potential driving hazards of Hazard Analysis, considering Control Measures

- Determination of Critical Control Points (PCC’s)

- Setting critical limits for each PCC’s

- Establishment of monitoring system for each PCC

- Establishment of corrective actions

- Establishment of Verification Procedures

- Establishing Documentation and Records Control

When we develop such steps considering existing regulations, it is important to take into account existing correlations. Therefore, we make available the table below for conference:

| Codex | ISO 22000 | Brc | Ifs | SQF |

| Team Building | 7.3.2 | 2.1 | 2.2.2 | Section 9 6.3.4 |

| Product Description | 7.3.3 | 2.3 | 2.2.3.1 | Section 9 |

| Identification of Intent to Use | 7.3.4 | 2.4 | 2.2.3.2 | Section 9 |

| Construction of the process flowchart | 7.3.5 | 2.5 | 2.2.3.3 | Section 9 |

| On-the-spot confirmation of the Flowchart | 7.3.5 | 2.6 | 2.2.3.4 | Section 9 |

| Listing of all potential driving hazards of Hazard Analysis, considering Control Measures | 7.4 | 2.7 | 2.2.3.5 | Section 9 |

| Determination of Critical Control Points (PCC’s) | 7.4.4/7.6.2 | 2.8 | 2.2.3.6 | Section 9 |

| Setting critical limits for each PCC’s | 7.6.3 | 2.9 | 2.2.3.7 | Section 9 |

| Establishment of monitoring system for each PCC | 7.6.4 | 2.10 | 2.2.3.8 | Section 9 |

| Establishment of corrective actions | 7.6.5/ 7.10.1/ 7.10.2 | 2.11 | 2.2.3.9 | Section 9 4.4.6 |

| Establishment of Verification Procedures | 7.8/8.4 | 2.12 | 2.2.3.10 | Section 9 4.5 |

| Establishing Documentation and Records Control | 4.2 | 2.13 | 2.2.3.11/ 2.1.1/ 2.1.2 | Section 9 4.2 |

Source: https://foodsafetybrazil.org/haccp-x-normas-gfsi-tabela-cruzada/

Considering the current market in the food production industry and in the light of the information we generate in this article, we consider that such companies that follow the standards established by the HACCP system are trustworthy by consumers due to the effective result of risk mitigation and contamination. Moreover, considering that large quality certifications such as ISO 9001 and international production standards promote the HACCP methodology, it is evident the recognition of this system.

Another important point about market competitiveness is that companies certified by the regulations that consider the HACCP methodology as ISO 22000 pass ahead regarding compliance with the sanitary laws in force in Brazil, mitigating risks of sanitary fines, recall, production closure, etc.

Now that you know what HACCP is and how it can be applied to identify, analyze and control the dangers associated with food production, distribution and consumption, what are you hoping to apply this quality system to your business?

Want to know more? Contact Kivalita Consulting and request a budget for ISO 22000 suitability without obligation! It costs a lot less than you think!